KOCKS rüstet auf

‘Made by KOCKS’: Unsere eigene KOCKS Fertigung hat ihren Sitz in Bremen. Dort fertigen wir seit über 50 Jahren die bewährten Kernelemente unserer Walzblöcke – heute nach Industriestandard 4.0. - content in english -

At KOCKS, our philosophy is simple: We believe in German engineering and manufacturing standards. Why? Because at the heart, quite literally, of the steelworks are the core components in the rolling process, i.e. the 3-roll stands, the 3-roll guides, and other critical noble parts.

The Reducing & Sizing mills are central to the production of SBQ steel bars and define the quality of the finished product. These parts that have to withstand extraordinary forces during operation are at the same time part of a finely tuned process. Thus we believe that our core technology has to be manufactured in our own technologically advanced workshop in Bremen, Germany.

AT KOCKS, INNOVATION IS A TRADITION

This belief, and our desire to build on our reliability in operation and process, gave rise in the summer of 2014 to Strategy KM2020 (‘KOCKS Manufacturing 2020’), envisaged as the manifestation of those seven decades of experience. It was decided that our manufacturing base in Bremen would undergo a major upgrade to become a showcase for our extensive knowledge of materials technology, production routes and processing methods. All of this combined with and enhanced by some of the most advanced technology available.

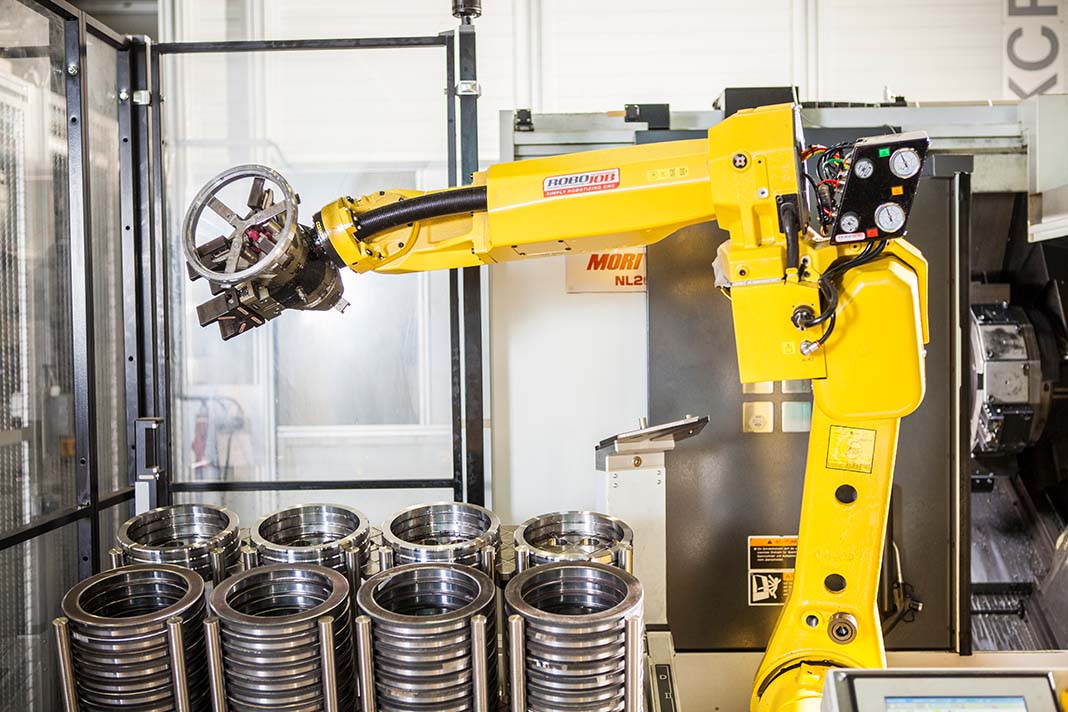

The manufacturing workshop was designed to comply with Industry 4.0 standards. Throughout the latter half of 2015 and into the second quarter of 2016 the plans were successfully and precisely implemented. The upgraded workshop at the Bremen site was succesfully commissioned in April 2016.

THE UPGRADES AT KOCKS MANUFACTURING MEAN FOR OUR CUSTOMERS

- State of the art technology: Heightened efficiency at the production level means better products with more features for the same price, in other words, an improved price-performance ratio.

- Improved production tolerances: The production route has been optimized, with work stages such as turning and milling being combined, assembly sequences tightened and production tolerances further improved; to achieve optimum capacity utilization and part automation, the machines have been equipped with an automatic feeding/loading and removal system.

Furthermore our customers can expect reliable order processing – remember, our philosophy is that we always deliver what we promise, on quality, on time, on budget and on target!

Our Strategy KM2020 is helping us to cultivate relationships, first of all with our customers: We deliver better products, faster and more efficiently, with an outstanding price-performance ratio, and the result for the customer is a highly competitive end product – we make your product gold!

But our employees also benefit from training and development programs that equip the teams at the workshop to work with the innovative technology. The customer can rely on a highly-trained and highly-motivated staff with the best results for his product.

As a family-run business, we are proud of our ability to operate successfully in an increasingly dynamic environment, and to play a leading role in markets where foreign competitors are improving quality and yet reducing prices – the latter mainly thanks to the shifting of production capacities to less expensive labor regions.

The McKinsey report on "The Future of German Mechanical Engineering" identifies three main competitive strategies as being the most promising: “Building better machines than the competition, building cheaper machines, or occupying a product niche.” We have chosen to build, not cheaper, but better, more efficient machines with even better products for our customers, and KOCKS Manufacturing 2020 is one of the central pillars of our strategy for future success.